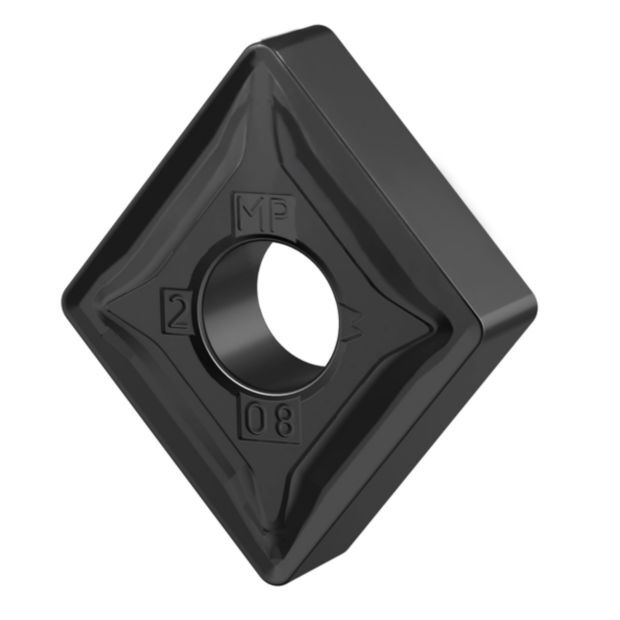

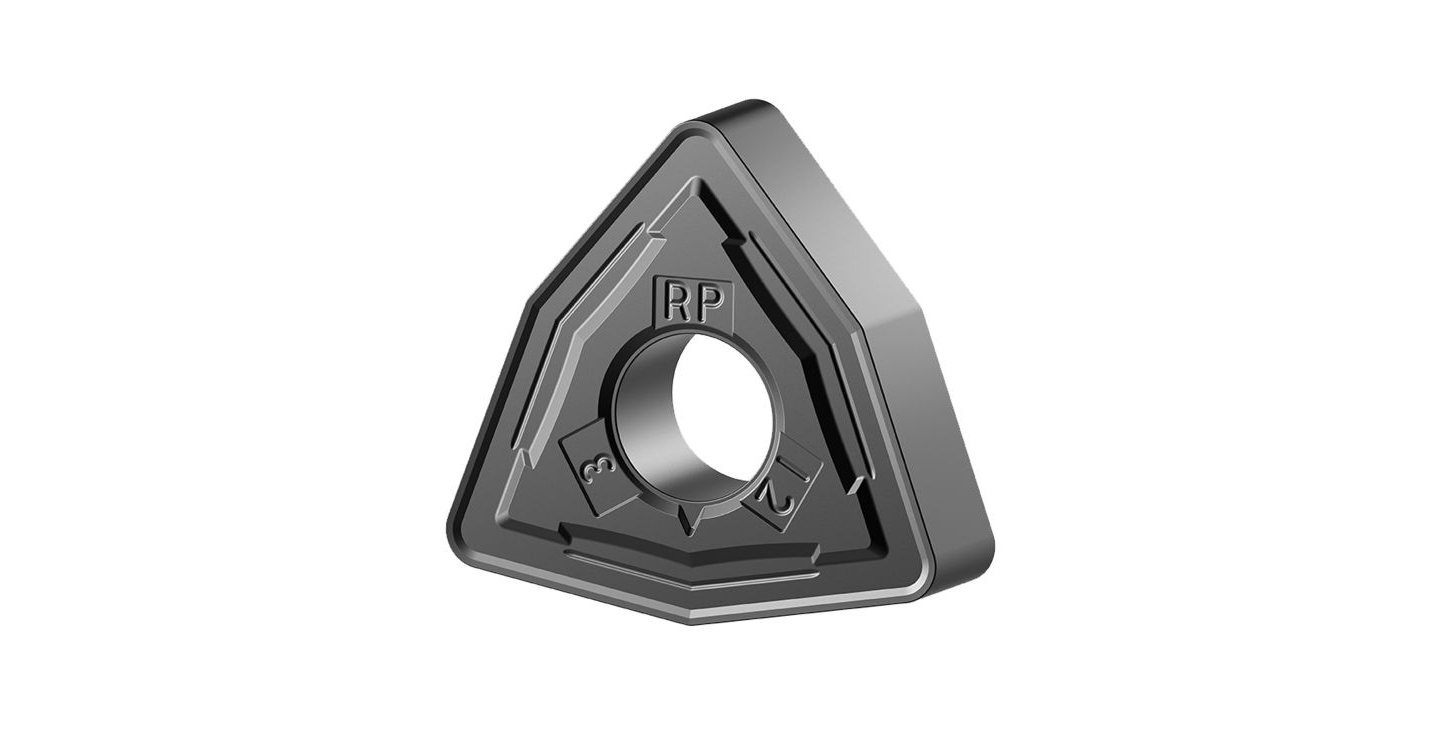

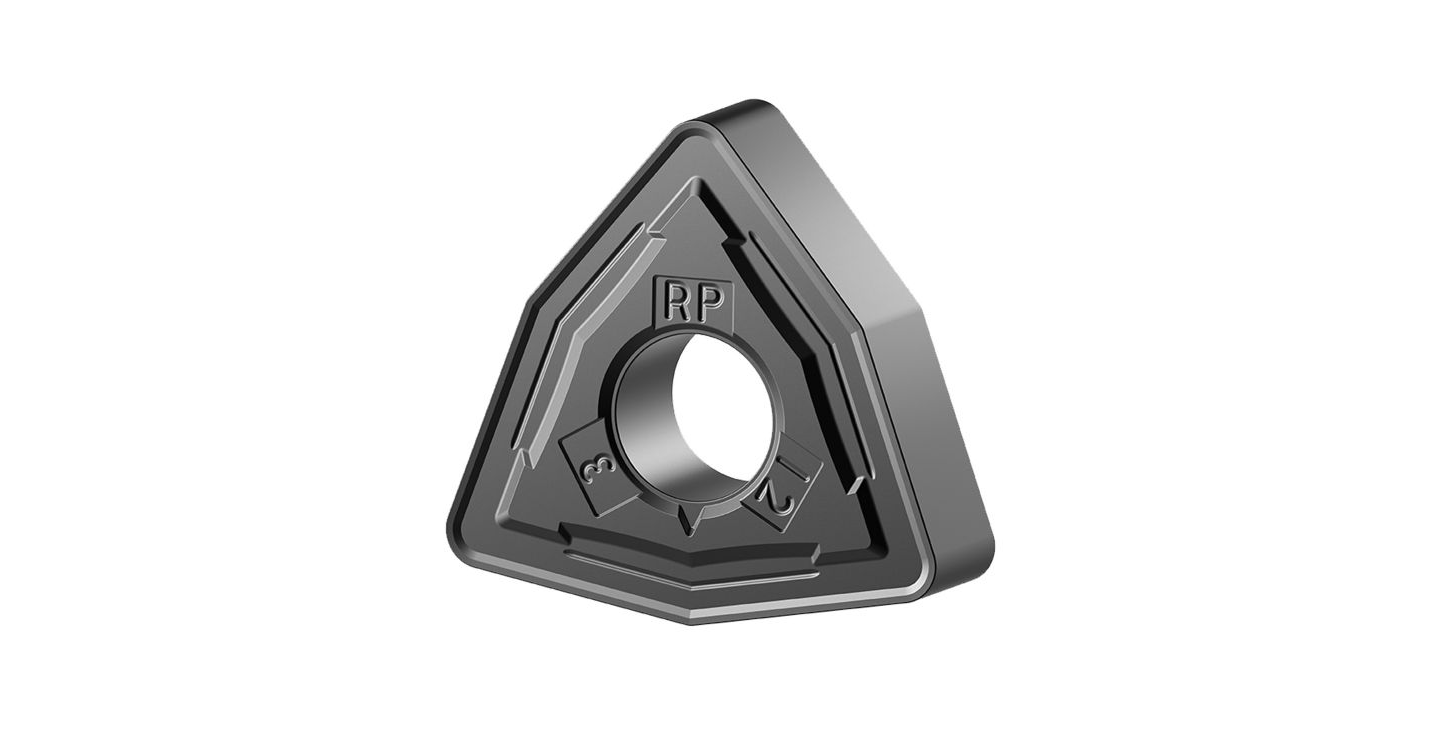

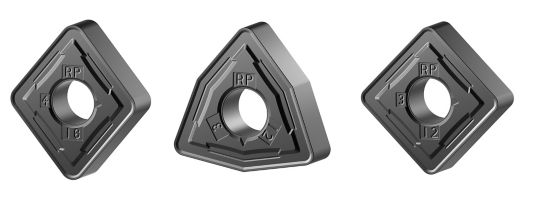

KCS10B

Turning Grade for High Temperature

Alloys

High-PIMS coating technology is characterized by:

- Smooth coating surface.

- Optimum layer adhesion, especially on sharp cutting edges.

- High depth-of-cut notching resistance.

- Long tool life, and high process reliability.

Applied on an extremely hard and wear-resistant ultrafine-grain carbide substrate, the KCS10B grade is ideal for medium machining and finishing operations.

The AlTiN PVD coating is ideal for iron-based alloys (S1), cobalt-based alloys (S2), and nickel-based alloys (S3).

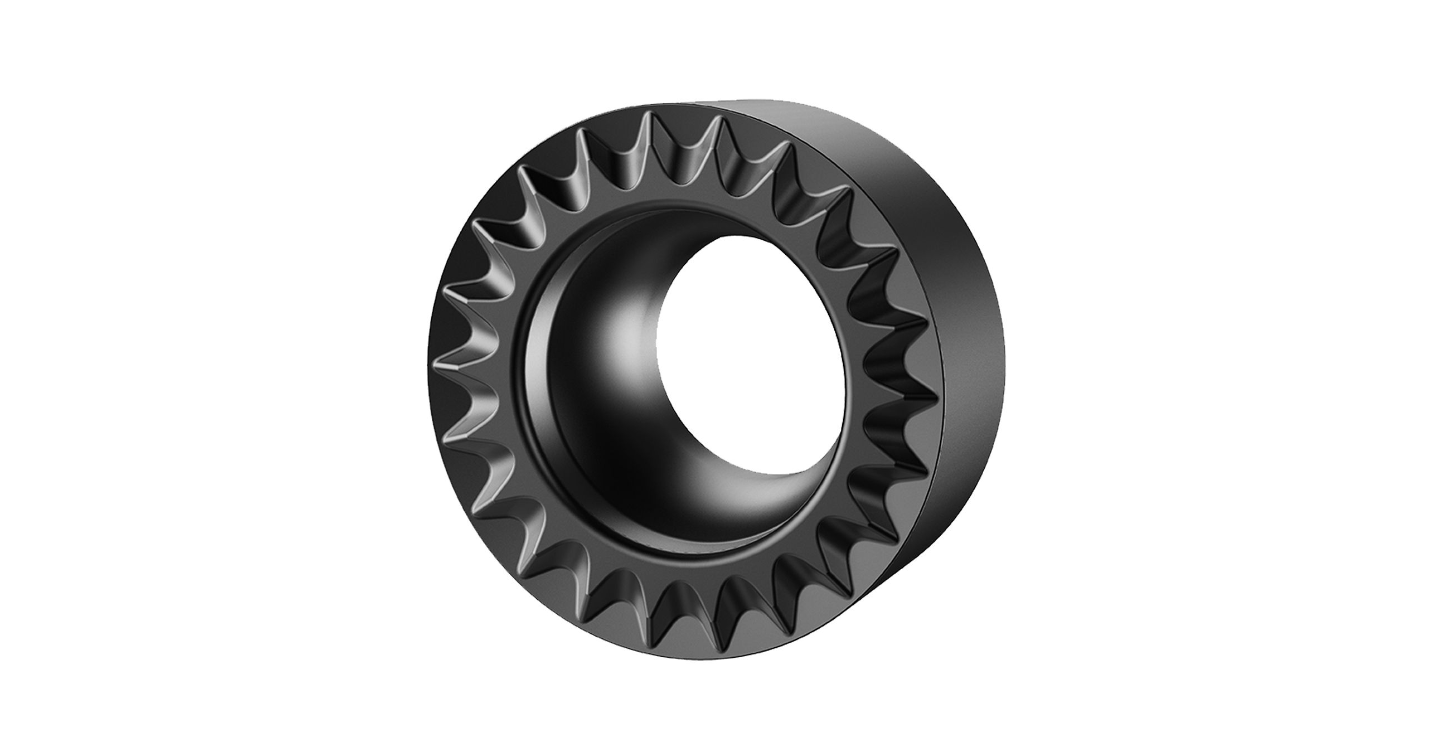

The New KCS10B coating provides easy wear identification.

The shown wear pattern indicates end of tool life is near.

An extremely smooth coating surface, reducing friction, providing longer tool life, increasing process reliability.