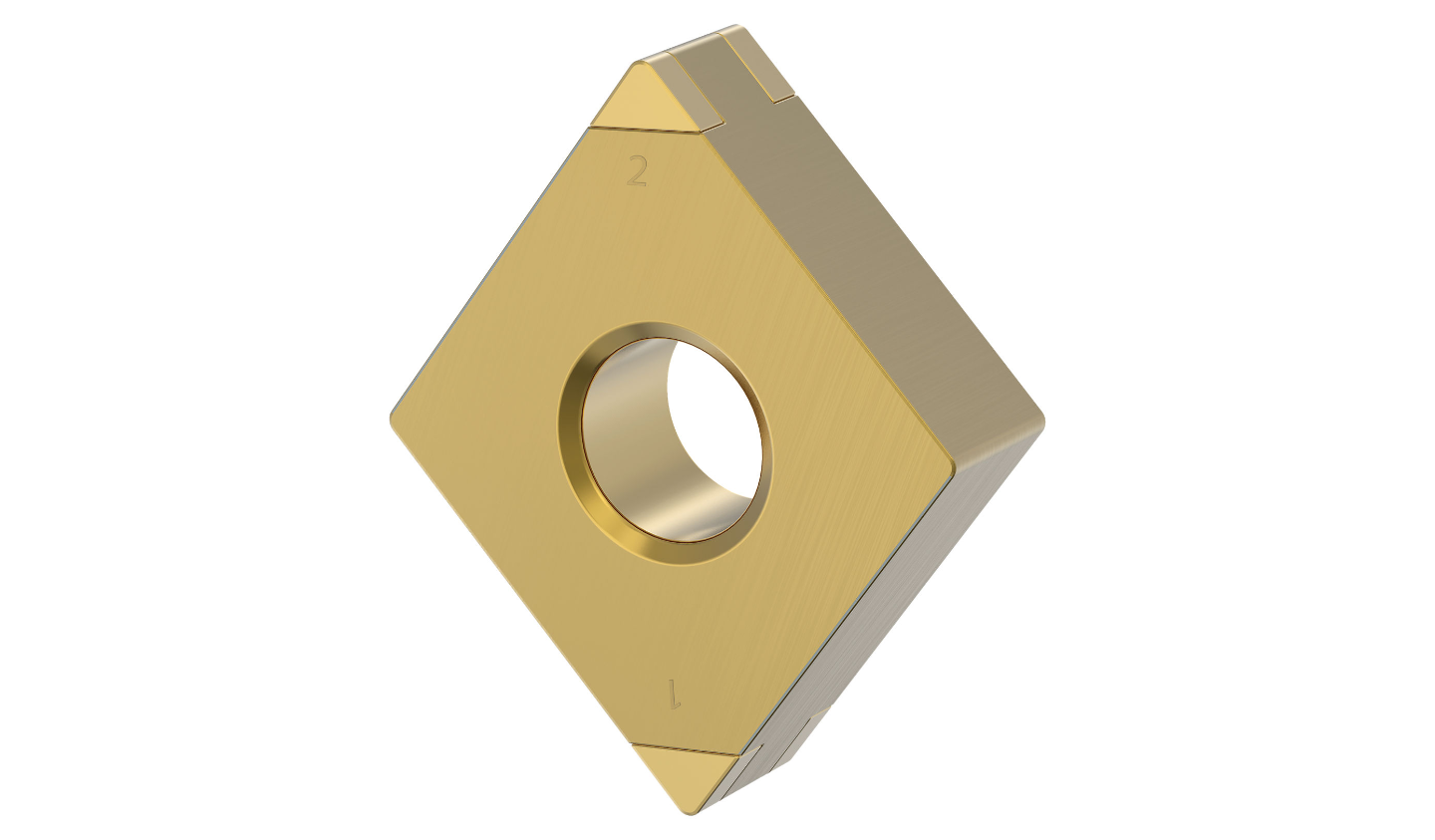

KBH10B™ & KBH20B™

Hard Turning PcBN Grades

Added Wear Resistance & Enhanced Wear Identification

- Designed for the precision machining of hardened steels & continuous to lightly interrupted cutting applications.

- Cost effective, doublesided design.

- All 4 cutting edges are numbered.

- Gold colour ensures wear progression is easy to identify.

- New coating enhances speed capabilities and tool life.

Grade Features

KBH10B™

Composition: A low content PcBN grade with a patented binder structure and a PVD TiN/TiAlN/TiN coating for added wear resistance and enhanced wear identification.

Application: Designed for the precision machining of hardened steels (>45 HRC).

It can be effectively applied on bearing steels, hot and cold work tool steels, high speed steels, die steels, case hardened steels, carburised and nitrided irons, and some hard coatings.

Available in a multi-tip format.

KBH20B™

Composition: A low content PcBN grade with a PVD TiN/TiAlN/TiN coating for added wear resistance and enhanced wear identification.

Application: Is the ideal PcBN hard turning grade for continuous to lightly interrupted cutting applications.

The structure, as well as the different edge preparations, enable repeatable workpiece tolerances, excellent surface fi nishes, and surface integrity. Typical applications are case-hardened steel components such as gears, shafts, and other drive-train components.